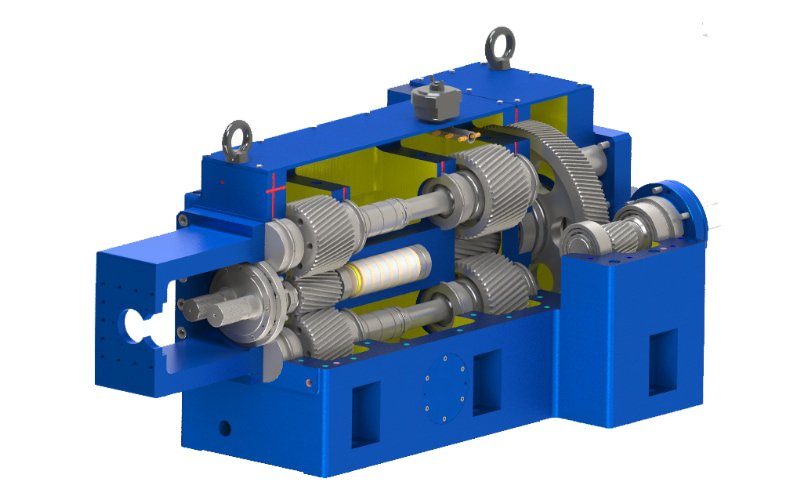

Description of Parallel Co-rotating Twin Screw Extruder

The screw diameter range is from ¢20mm to ¢200mm. This extruder is able to perform more delicate processing tasks, precise process controls to fulfill intricate and sophisticate processing purpose. Better dispersion, more accurate temperature controls and higher throughput have been integrated and optimized further.

Applications of Parallel Co-rotating Twin Screw Extruder:

1.Filler Masterbatch

2.Color Masterbatch

3.Additive Masterbatch

4.Melt Blown PP Compounding

5.Biodegradable Plastic

6.Cable Compounding

7.Engineering Plastics Reinforcing (GF)

8.PVC Compounding

9.Reacting Direct Extrusion

10.Thermoplastic Elastomers

Main Parts details of Parallel Co-rotating Twin Screw Extruder:

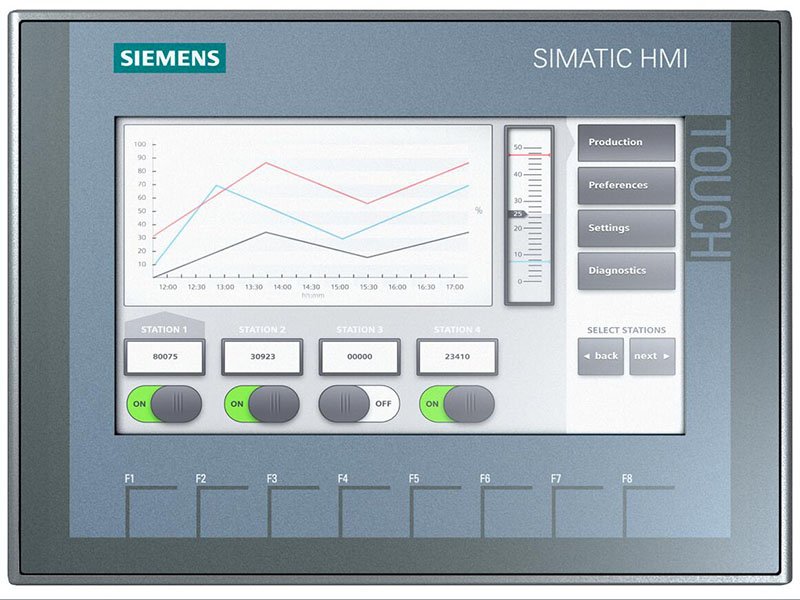

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

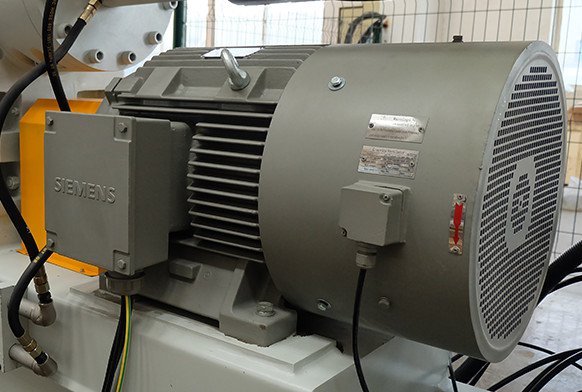

Driven Motor

✔ Using Siemens brand safety and energy saving motor.

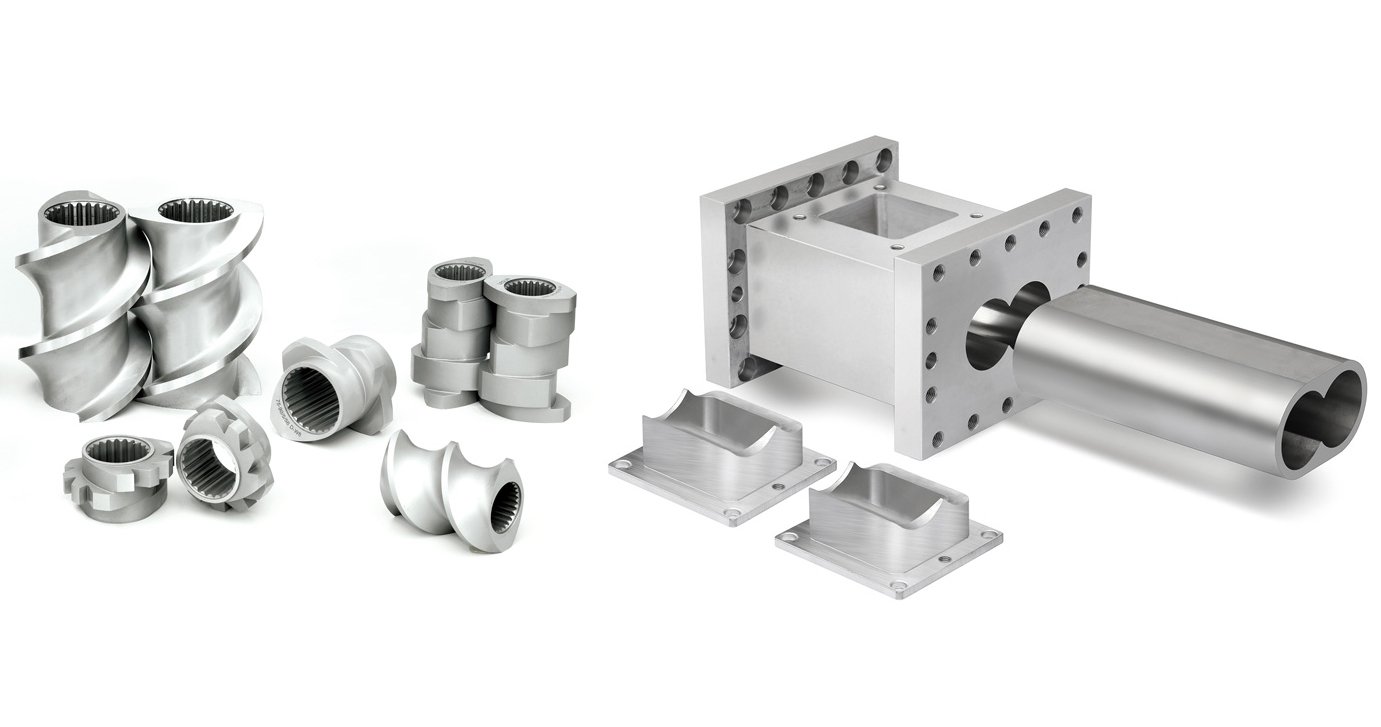

High Precise Barrel and Srew elements

Heating System

✔ Instead of using traditional casting heaters (outside the barrel), we use cartridge heaters, which are made in Germany and are inside the barrel. This will save energy, and the polymer will melt mostly by heating, not kneading elements. So, the shelf life of screws and barrels are longer, and the quality of compounding is better.

Control Panel

✔ With two input and output on each barrel, more uniform cooling and fast cooling.