Description of PVC Pipe Extrusion Line

1.To provide professional plane for turn-key project with belling, printer, mixer, and crusher.

2.There’s PLC+HMI control available for more convenient operation.

3.PVC Pipe what can produce:

✔ Pressure piping

✔ Water distribution systems

✔ Irrigation plants

✔ Non pressure piping

✔ Sewer systems

✔ Waters discharge systems for civil and industrial buildings

✔ Meteoric waters discharge

✔ Venting systems

✔ Industrial applications

✔ Cable conduits

✔ Flexible pipes

✔ Gardening hoses

✔ Medical pipes

✔ Fluids suction

✔ Protection sheathing for electric cables

Features of PVC Pipe Extrusion Line

Material:

|

PVC, UPVC, CPVC

|

Cavities:

|

One /Two/Four /Six/Eight cavity

|

Screw diameter:

|

20 - 200mm

|

L/D ratio:

|

10 - 40

|

Main Parts details of PVC Pipe Extrusion Line

Siemens PLC Control System

✔ Siemens PLC + HMI Control to assure the machine running precision and easy operation

✔ Intelligent & centralized control

✔ Automatic preheating

✔ Diagnose function

✔ Remote monitoring

✔ Multiple-language

✔ Intelligent alarm system

✔ Formula management

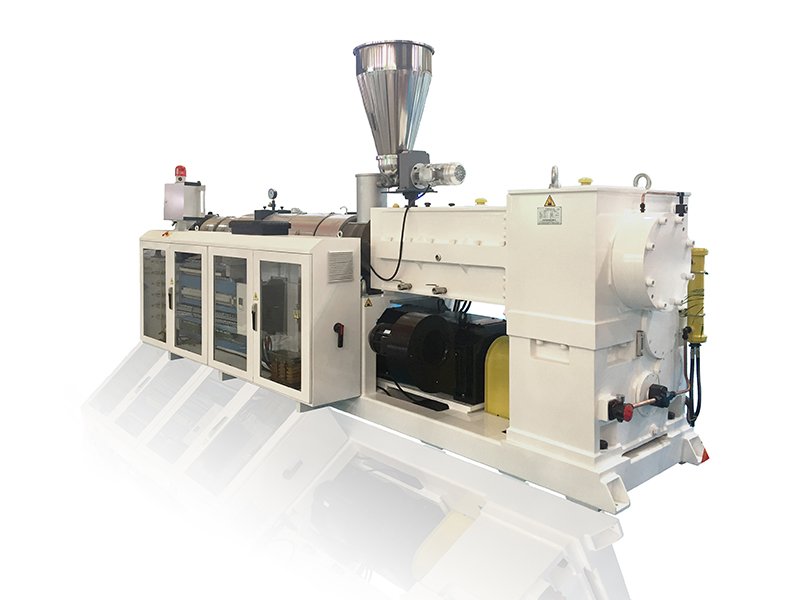

Extruder

✔ Material: 38CrMoAl Or Bimetallic

✔ Specified screw design for better material plasticizing &mixing effect, For high Filling formula, bimetallic screw and barrel canguarantee perfect solution

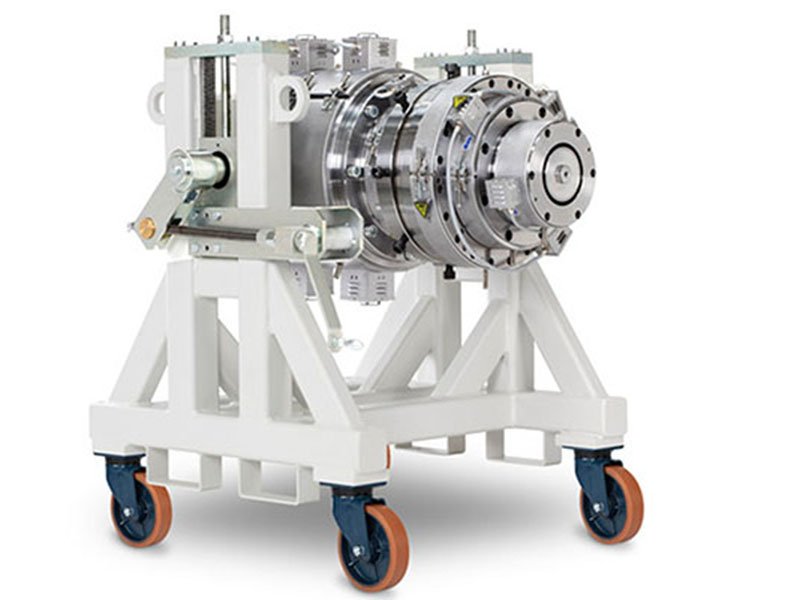

Die head

✔ Precision structure throughout assuring perfect uniformity of material

✔ Excellent uniform distribution

✔ Precise melt transport

✔ Suitable shear stress on the wall of the flow channel, avoiding material deposits

Vacuum Tank

✔ Clibration sleeves: Copper material and minimum friction

✔ Tank material: 304L Stainless steel

✔ Vacuum calibration tank adopts high-efficiency two chamber and large length design, providing faster calibration and More efficient cooling

✔ Fast Diameter Changing

✔ Excellent Uniform Cooling

✔ Easy Vacuum Control

✔ Precise Flow Control

Water Cooling Tank

✔ Tank material: 304L Stainless steel

✔ Fast Diameter Changing

✔ Excellent Uniform Cooling

✔ Precise Flow Control

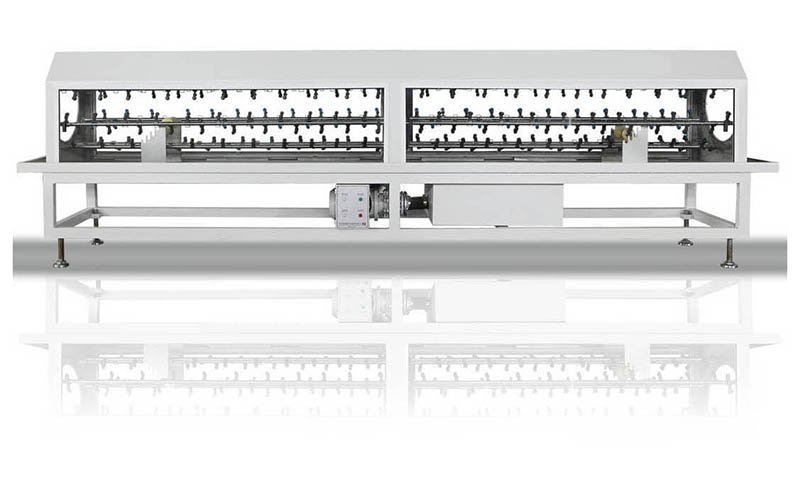

Haul Off Machine

✔ Independently driven caterpillars

✔ Energy efficient

✔ Accurate and consistent pulling

✔ Long caterpillar contact length

✔ Easy system for changing pads

✔ Strong Chassis construction for accurate and repeatable pulling

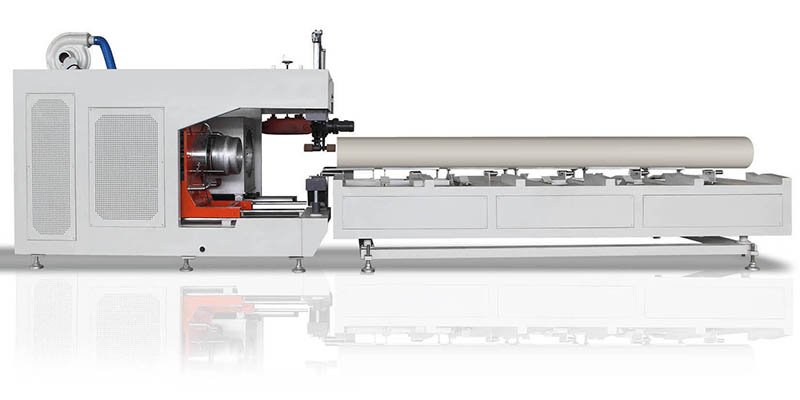

Cutter

✔ Precise Cutting

✔ Energy efficient

✔ Universal clamping system

✔ Electrical synchronization and CNC Control

✔ Hydraulic feeding of blade providing perfect chamfering processing and cutting surface

PVC Belling Machine

✔ Full automatic: it can be installed inline or used seperately

✔ Air-cooling and Water cooling system.

✔ Suitable for PVC & PP building sewerage and pressure pipes.

✔ Touch screen and PLC is used for the operation

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc