Description of PMMA/ASA+PVC Glazed Roof Tile Making Machine:

1.High reliability of our lines, suitable for high outputs

2.Energy saving technology

3.Unique screw extruder design to ensure the high plasticilization

4.Experienced progressing skill to assure the high production efficiency and product quality

5.Easy operation and machine maintenance to save more labor for customers

6.User friendly turn-key project (including know-how transfer)

Features of PMMA/ASA+PVC Glazed Roof Tile Making Machine:

2.Width range: 1000 - 2500mm 6.Output range: 300 - 500kg/h

1.Material: PVC, PMMA/ASA

2.Width range: 720 - 1130mm

3.Thickness: 0.8 - 3mm

4.Layers structure: Single layer/Three layers/Four layers

5.Output range: 350 - 700kg/h

Applications of PMMA/ASA+PVC Glazed Roof Tile Making Machine:

1.For car trunk cover board, trunk clapboard, trunk carpet substrate, side wall decoration board, ceiling etc. interior place.

2.For manufacturing different kinds of high strength packing box. It is mainly used as decorative board of the automobile ceiling and indoor decorative materials.

Main Parts details of PMMA/ASA+PVC Glazed Roof Tile Making Machine:

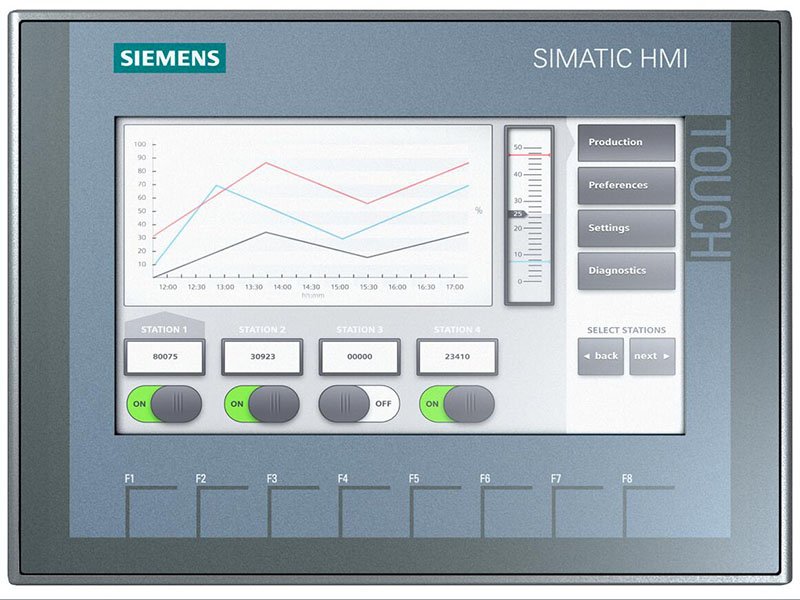

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

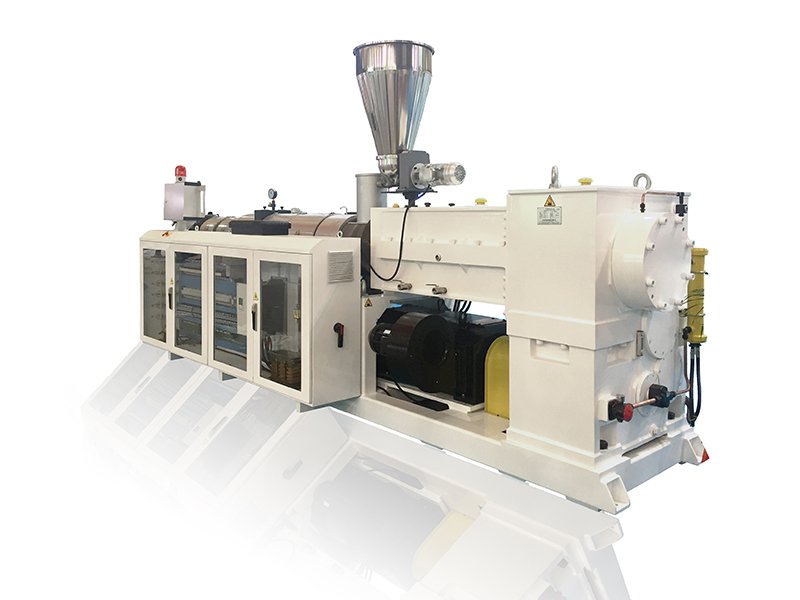

WSJZ Series Twin Screw Extruder

✔ Unique screw extruder design for PVC to ensure the high plasticilization

✔ Quality Gearbox and Engin

Flat Die Head

✔ Processing: High precision CNC to assure the high precision extruding

✔ Material: High quality Geman mould alloyed steel

Embossing Roller System

✔ Qty of Roller: 2PCS

✔ Diameter of roller: 300mm

✔ Upper roller is used as the embossing roller to emboss different design Texture on the top surface of the Tile.

Forming table

✔ Material of forming block: Aluminium

✔ Machine frame: Strong thick steel frame to assure machine stable running.

✔ Control: Siemen PLC

Cutting Machine

✔ Cutting method: Saw cutting

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc