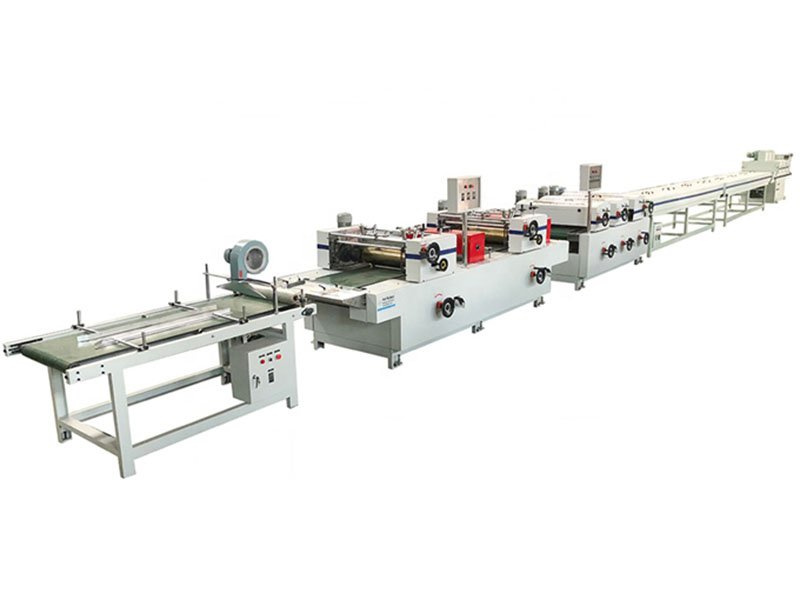

Features of SPC Flooring Extrusion Line

1.Material available: PVC

2.Width: 1100mm

3.Sheet thickness: 2-8mm

4.Output: 700-800kg/h or Customized

Description of SPC Flooring Extrusion Line

1.Surface is laminated with different design decoration film

2.Wear-resisting layer is laminated on top of the surface

3.The surface is embossed with different design

4.Sound insulation cushion layer is laminated at bottom side

5.High precision Siemens PLC + Touch screen route control system to assure the high quality sheet production.

6.Unique screw extruder design to ensure the high plasticilization.

7.World brand facous pressure and temperature controllers to ensure the machine running in high accuracy.

8.Experienced progressing skill to assure the high production efficiency and product quality.

9.Easy operantion and machine maintanence to save more labor for customers.

10.Free training: technical process, formula and know-how.

User friendly turn-key project (including know-how transfer).

Main Parts details of SPC Flooring Extrusion Line

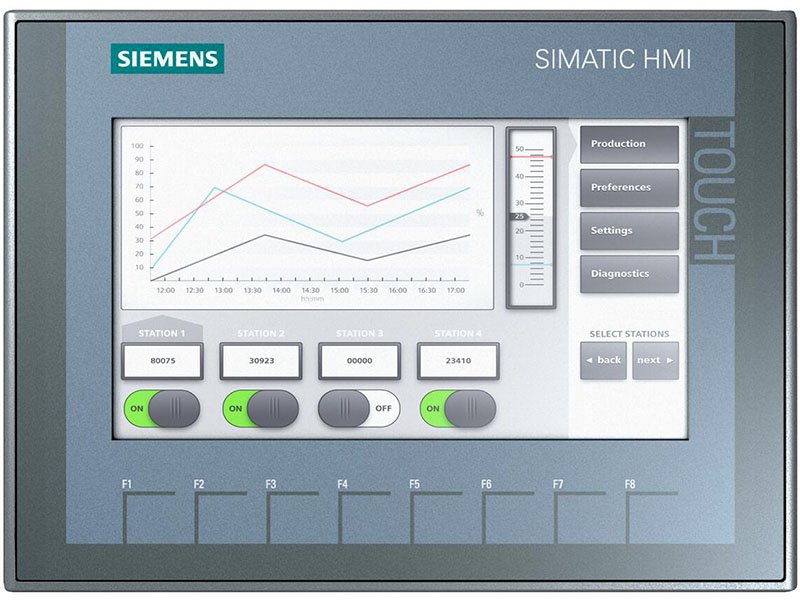

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

WSJZ Series Conical Twin Screw Extruder

✔ Unique screw extruder design to ensure the high plasticilization

✔ High efficiency design to improve the production capacity

✔ Siemens Energy saving motor

T Die head

✔ T Type

✔ Special design for SPC flooring

✔ Regulation bolt on mould lips, the mould lips is changeablefor more different thickness sheet

Roller Calender System

✔ Type: Four rollers

✔ Flattening rollers: 2PCS

✔ Deviation rollers: 2PCS

✔ Unwinding roller: 2PCS

✔ Tension control: Magnetic powder brake

✔ Corrector: 1 set

✔ Constant tension control system: 1 set

✔ The rolls are driven independentlyby AC motor,Controlled by ABB inverter

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc

UV Coating Machine

✔ UV coating on top of the SPC Flooring

Slitting and Slotting Machine

✔ litting SPC Flooring board into floor size and Slotting the floor edge for connection.