Description of PP PC Hollow Sheet Extrusion Line:

1.High reliability of our lines, suitable for high outputs

2.Energy saving technology

3.Unique screw extruder design to ensure the high plasticilization

4.Experienced progressing skill to assure the high production efficiency and product quality

5.Easy operation and machine maintenance to save more labor for customers

6.User friendly turn-key project (including know-how transfer)

Features of PP PC Hollow Sheet Extrusion Line:

Material:

|

PP, HDPE, PC

|

Width range

|

1200 - 3000mm

|

Sheet thickness rang

|

2 - 16mm

|

Layers structure:

|

Monolayer, 2-layer and 3-layer and more

|

Product geometry:

|

From 2 to 6 walls

|

Output range:

|

300 - 700kg/h

|

Main Parts details of PP PC Hollow Sheet Extrusion Line:

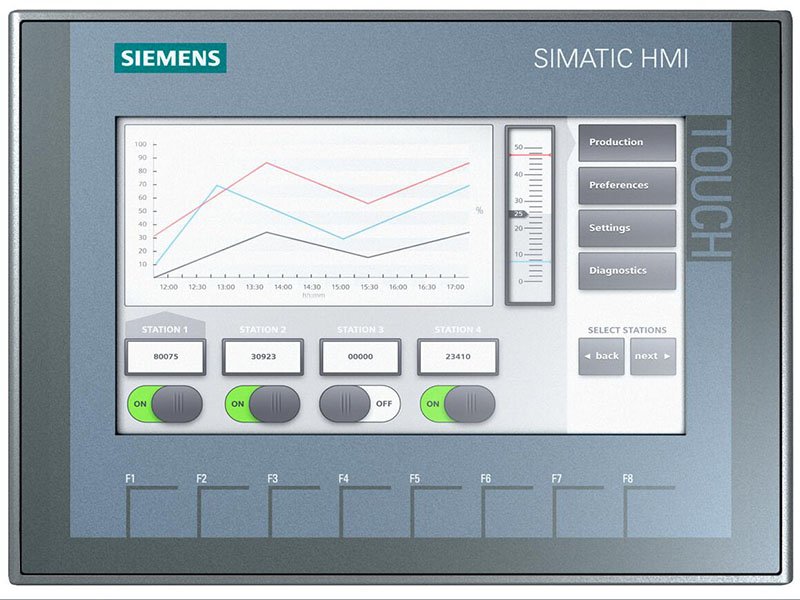

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

Drier Hopper

✔ Hopper dryers are used for drying hygroscopic plastics, such as PP, PE, PS and ABS etc., which can reach the highest drying temperature up to 160℃.

✔ In addition, multiple accessories are optional to realize different functions, such as recycling hot air and filtering metal impurities in the materials. With the floor stand, it makes floor mount of the machine available.

WSJ Series Single Screw Extruder

✔ Unique screw extruder design to ensure the high plasticilization

✔ High efficiency design to improve the production capacity

Screen Exchanger

✔ Hydrautic changing with double position

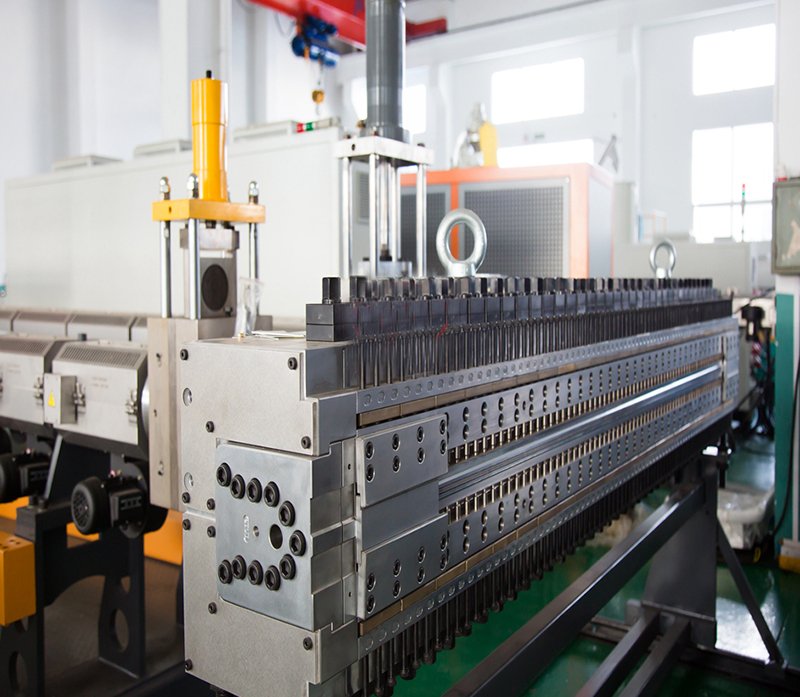

Hollow Die Head

✔ Feedblock suitable for multilayer PET processing up to 5 layers.

✔ Flat die with manual or automatic thickness control.

✔ Internal deckling system available on request.

Calibration Table

✔ Pairs of Calibration blocks: 2 or 3 pairs

✔ Clamping method: Pneumatic

✔ Cooling method: Water cooling

✔ Processing: High precision CNC

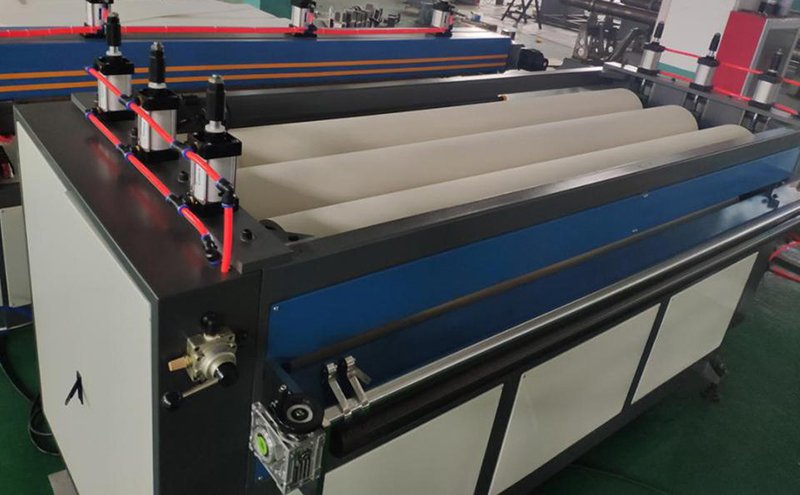

6 Pairs of Roller Haul Off Machine

✔ Roller Qty: 6 Pairs

✔ Clamping method: Pneumatic

✔ Roller material: Rubber

3 Pairs of Roller Haul Off Machine

✔ Roller qty: 6 Pairs

✔ Clamping method: Pneumatic

✔ Roller material: Rubber

Heating Oven

✔ Heating method: heating pipe

Cutting machine

✔ Cutting method: Blade cutting

✔ Clamping method: Pneumatic

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc