Description of PET Sheet Extrusion Line:

1.Using 100% reccycled bottle flakes without any dry crystallization.

2.Effective energy saving technology with a very low energy consumption.

3.Screw and the barrel design adopts the “building block type”structure. It has good interchangeability and can be used in any combination according to different material processing.

4.The innovative and automatic automatic exhaust device is designed to automatically eliminate the moisture and moisture of the recycled materials during the operation of the main engine, successfully solving the problem of agglomeration and bubbles in the final sheet.

5.More user-friendly and intelligent close-loop control

Features of PET Sheet Extrusion Line

|

Material:

|

PET, PETG and 100% PET bottles flakes

|

Width range:

|

600 - 1500mm

|

Layers available:

|

1 layer A; 3 layers A-B-A; 5 layers A-B-C-B-A

|

Sheet thickness range:

|

0.15 - 2mm

|

Output range:

|

400-1500kg/h

|

Speed of the line:

|

Max. Up to 50m/min

|

Main Parts details of PET Sheet Extrusion Line:

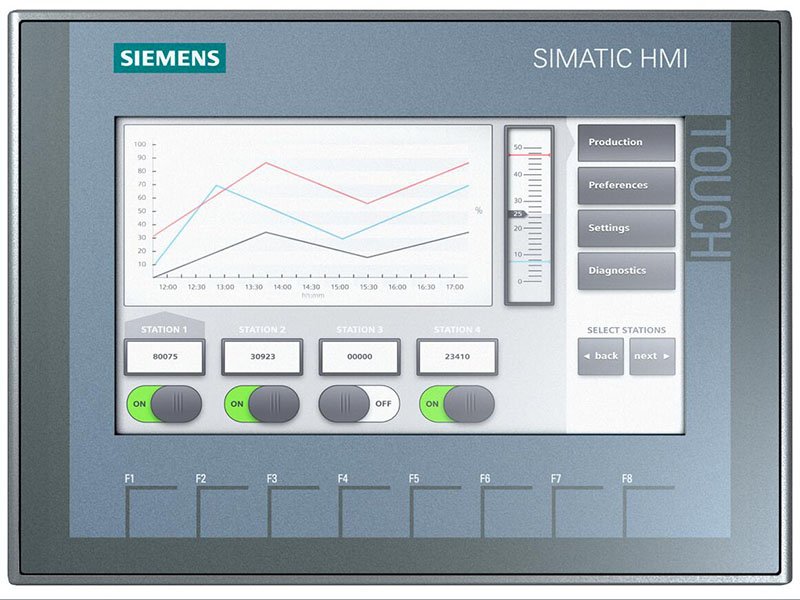

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

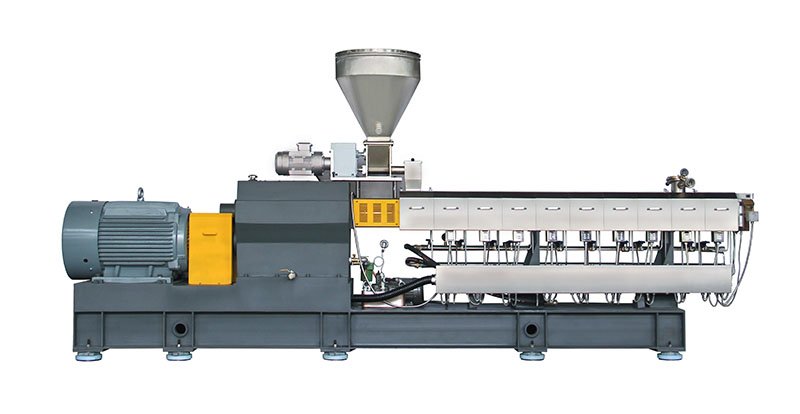

Parallel Twin Screw Extruder

✔ The screw to the modular structure , multiple portfolio, its extensive scope, not only adapted to the production of PET, but also suitable for the PLA and starch biodegradable materials production.

✔ Barrel used double exhaust outlets, vacuum exhaust ensure full emit water vapor.

✔ Extruder equipped with molten metering pump quantitative output, and set up the pressure and speed closed Ioop auto control.

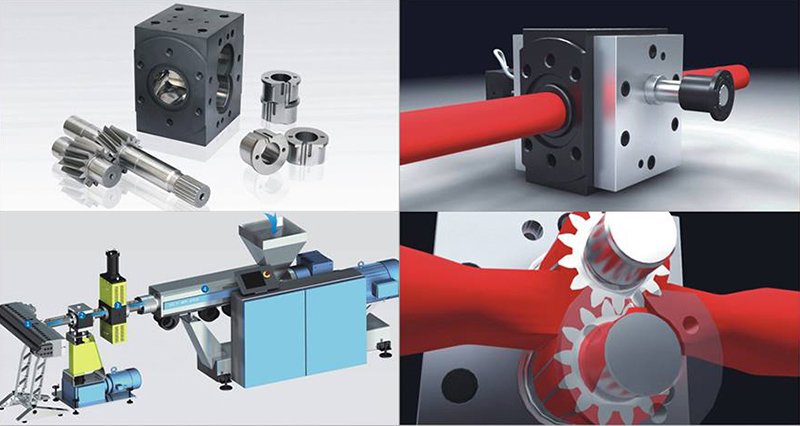

Melt pump

✔ Ensure the material stable flowing to make high quality product.

Feedblock and Flat die

✔ Feedblock suitable for multilayer PET processing up to 5 layers.

✔ Flat die with manual or automatic thickness control.

✔ Internal deckling system available on request.

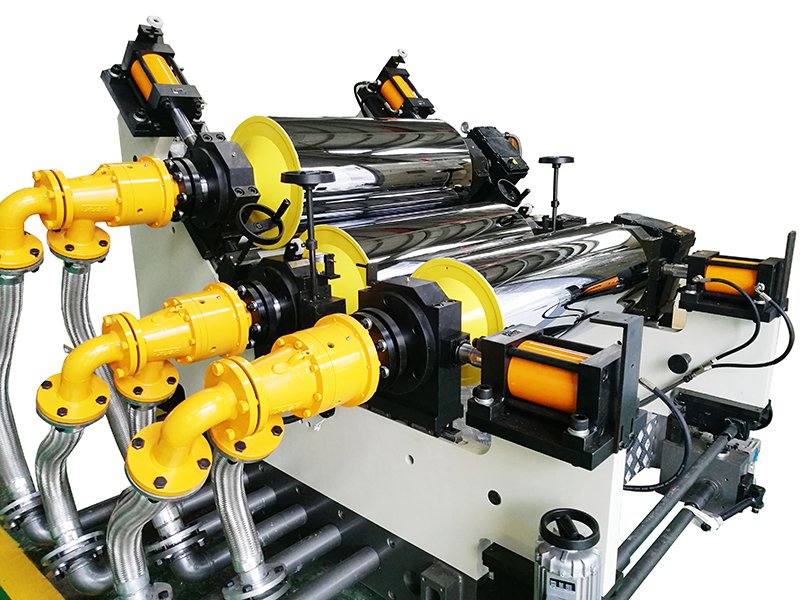

3-Roller Calender System

✔ Two types structure: Horizontal and L type

✔ Different diameters for inlet, middle and exit rolls: 400 - 700 mm

✔ High pressure clamping force.

✔ The rolls are independently driven by Servo motor

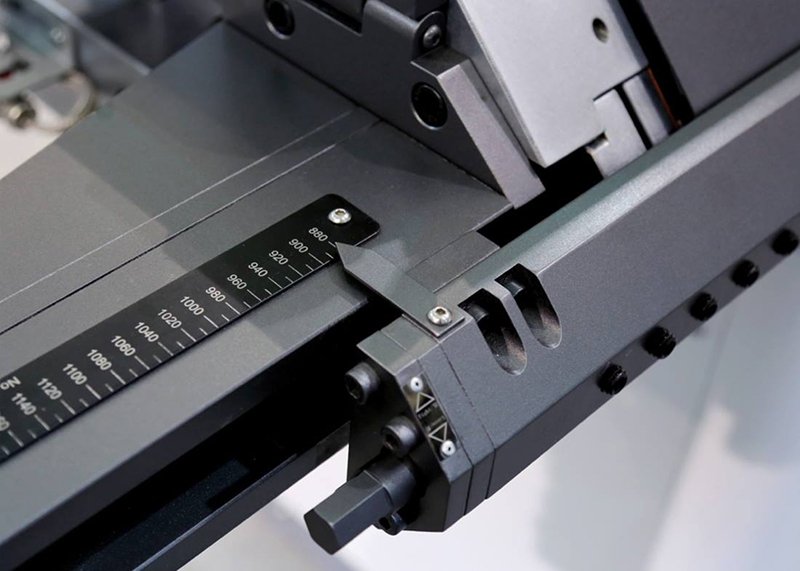

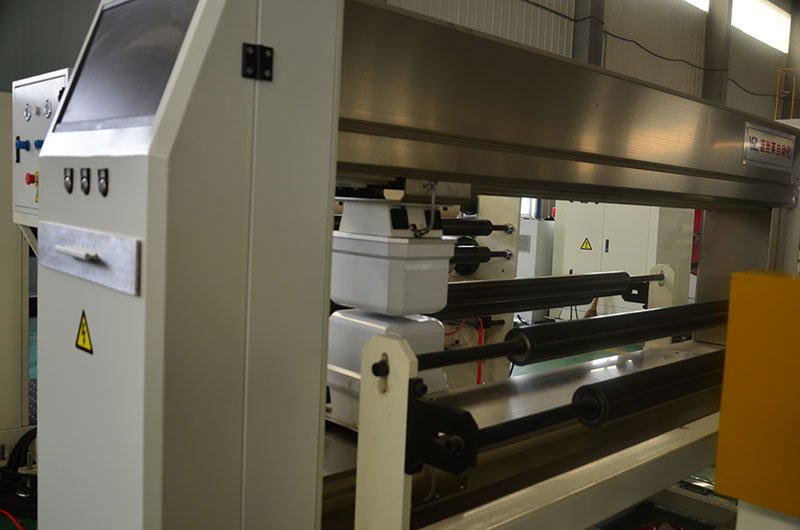

In-line Thickness Measuring System

✔ A measuring sensor detects the thickness without any contact with the sheet.

✔ Also available for fully automatic die/thickness

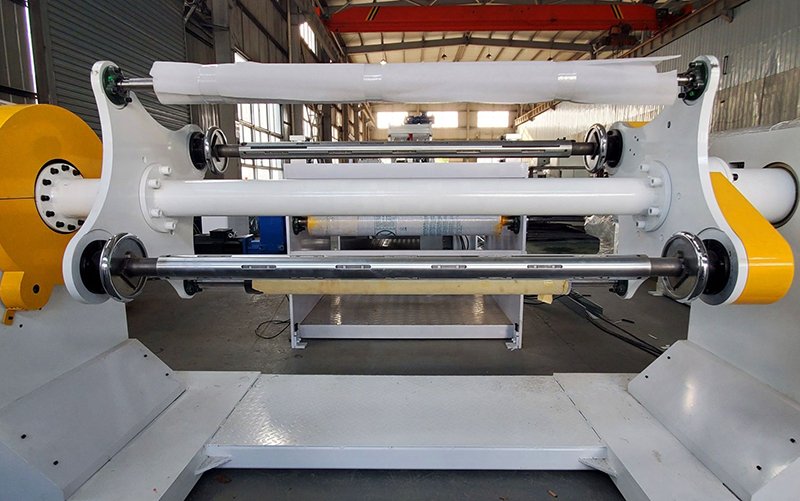

Winding Machine

✔ Semi-automatic unit, standard size roll diameter 1200mm or with jumbo roll

✔ Fully automatic unit, size roll diameter max 1000mm

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc