Description of PVB Film Extrusion Line:

1.Siemens Touch + PLC control to assure the machine running precision and easy operation

2.Full automatic material dosing and uploading

3.Fully automatic mold with thickness gauge

4.Special designed Parallel twin screw extruder to ensure the excellent PVB material plasticilization and stable extrusion.

5.Cooling method: Water cooling and Roller cooling

6.Full set of servo motor, with the servo controller to make the equipment run more accurately.

Features of PVB Film Extrusion Line:

Material available:

|

PVB

|

Output range

|

400 - 800kg/h

|

Width range

|

Up to 3600mm

|

Min. Sheet thickness

|

0.38-1.52mm

|

Layers structure

|

A, A/B, A/B/A

|

Shrinkage rate

|

≤2%

|

Max. Production speed

|

12m/min

|

Main Parts details of PVB Film Extrusion Line:

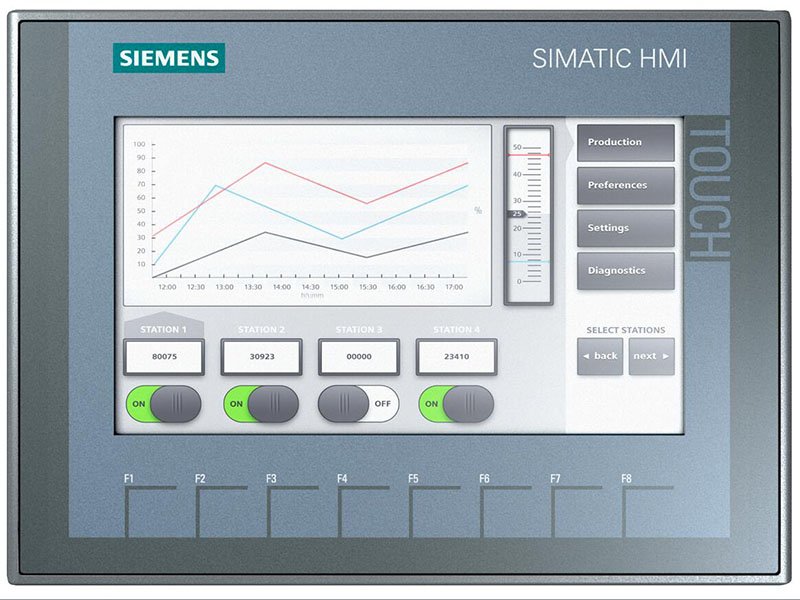

Siemens PLC Control System

✔ Siemens Touch + PLC control to assure the machine running precision and easy operation

Full automatic material dosing and uploading

✔ Hi precision material doing system

✔ Automatic material uploading system

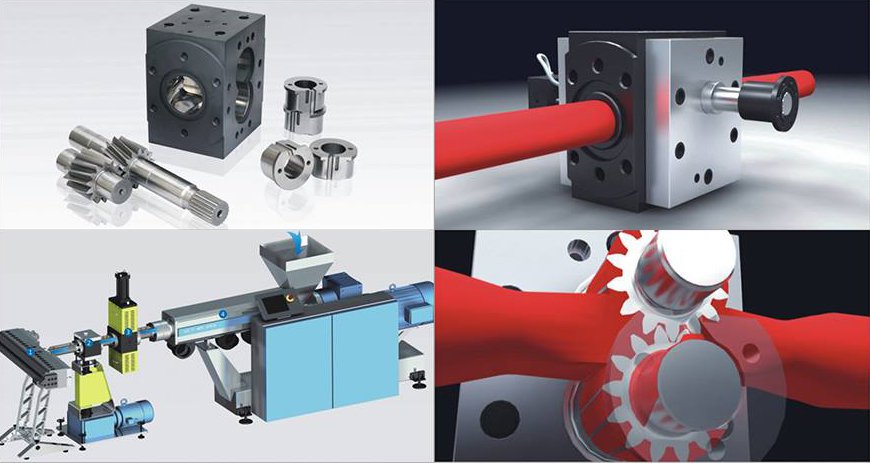

Parallel Twin Screw Extruder

✔ Parallel twin screw extruder model: the special screw design of the extruder ensures that the excellent plasticilization and stable extrusion

✔ Barrel used double exhaust outlets, vacuum exhaust ensure full emit water vapor

✔ Extruder equipped with molten metering pump quantitative output, and set up the pressure and speed closed Ioop auto control

Screen Exchanger

✔ Hydrautic changing with double position

Melt pump

✔ Ensure the material stable flowing to make high quality product

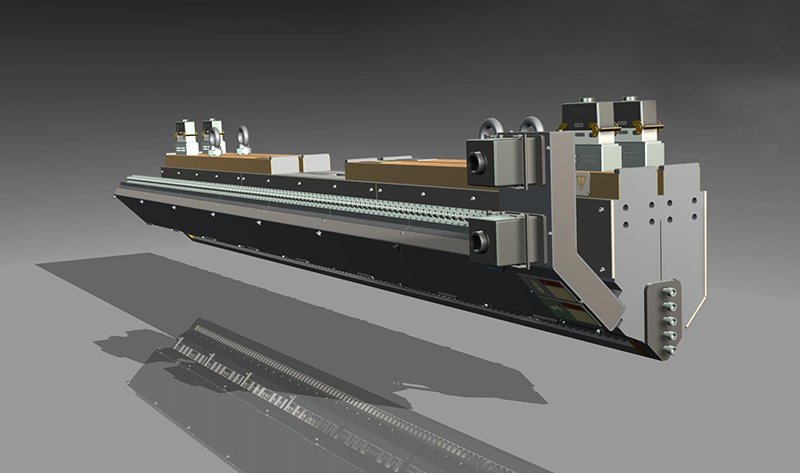

Automatic Flat die

✔ Full automatic thickness control Flat die head for option

✔ Internal deckling system available on request

Water Cooling or Roller Calender Cooling System

Thickness Measuring Device

Brand: ScanTech Or customized

Winding Machine

✔ Double position winder, standard size roll diameter up to 600mm or Customized

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc