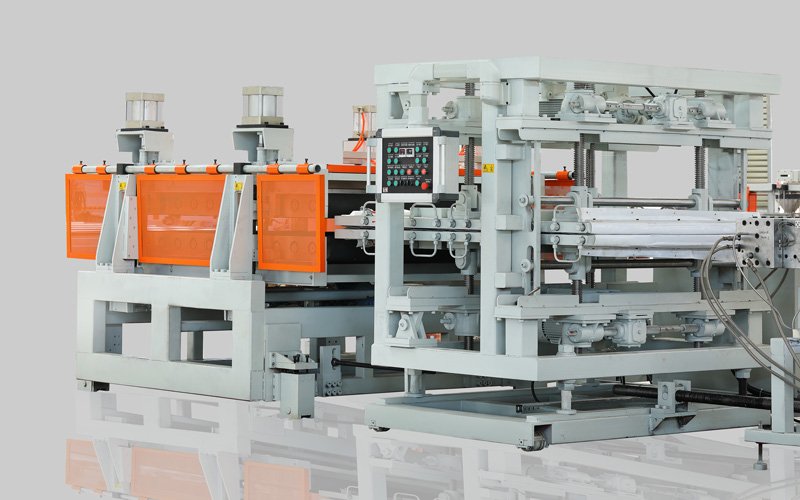

Description of XPS Foam Board Extrusion Line:

1.Full automatic line from the material supplying to product package.

2.CO2 and alcohol are used as blowing agents, more enviremental than CFC and HCFC.

3.100% recycled materials, both recycling EPS and GPPS are available.

4.Llower energy consumption, with high performance-cost.

5.Turn-key Projects: Our service covers workshop design consulting, warehouse logistic management, recipe management operation, and maintenance training under the strong support of our Technical team.

6.All our machines are CE certified.

Features of XPS Foam Board Extrusion Line:

Material:

|

GPPS

|

Foam agent applicable:

|

CO2+Ethanol, DME, HFC, HFO, butane, pentane and LPG etc

|

Product width:

|

600/900/1200mm

|

Product thickness:

|

10 - 200mm

|

Output range

|

200 - 3000kg/h

|

XPS Foam board density range

|

25kg/m3-50kg/m3

|

Main Parts details of XPS Foam Board Extrusion Line:

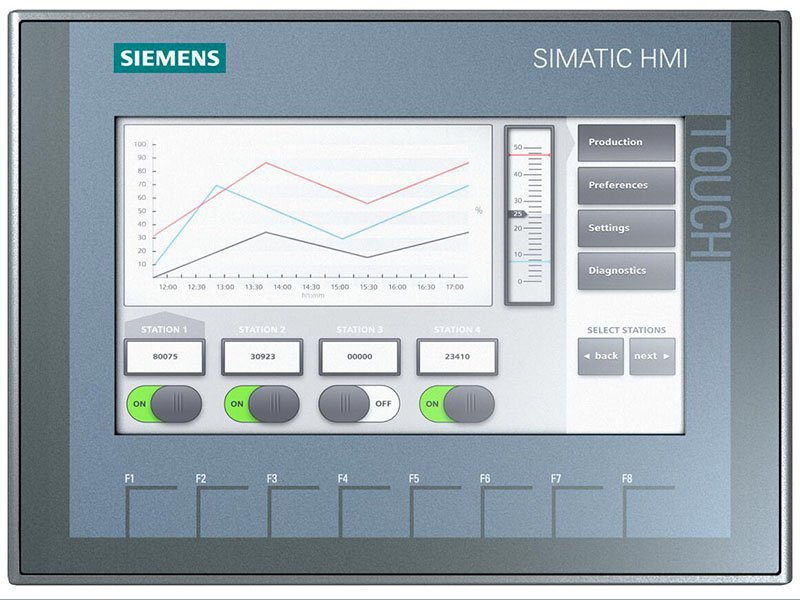

Siemens PLC + HMI Control System

✔ Siemens PLC + HMI control to assure the machine running precision and easy operation

Automatic Material Supply system

✔ Hi precision material doing system

✔ Automatic material uploading system

High Torque Parallel Twin Screw Extruder

✔ Maintain the lowest possible melt temperature during processing

✔ Minimize the usage of flame retardant additive whilst maintaining the same flame retardancy level

✔ Keep the colour of the product bright and fresh

✔ Excellent for producing high compressive strength boards Highly modularized barrels and screws as well as blowing agent injection flange allow twin screw extruders to have wider flexibility and suitability.

✔ German Brand CO2 metering pump to assure high precise metering and stable running.

Innovative Cooling Single Screw Extruder

✔ Temperature control is extremely important when extruding foam. The innovative barrel design has 80% more cooling capacity than traditional.

✔ The innovative screw design has also increased renewal rate of molten materials to ensure the cooling efficiency and homogenization of the polymer, 30% energy consumption saving.

Downstream

✔ We customize the downstream system according to customer’s plant requirements.

✔ The Surface planner, surface groover, embossing, shiplap edge, and tongue & groove edge accessories can be online or offline to suit the product being produced.

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc