Description of PVC Foam Board Extrusion Line:

1.The complete set of equipment adopts Siemens PLC, closed control, one-speed speed increase, easy to operate.

1.Material formulation:we can input 100%recycled material.

2.Application of PVC Foam board:

1)Construction industry:

Building formwork board, outdoor board, indoor decoration board, residential house board, office board, separation wall of public building, commercial decoration frame, board used in dust-free room

2)Furniture and Household decoration:

Bathroom cabinet board, kitchen cabinet board, furniture board, home decoration board

3)Advertisement industry:

Screen printing, computer engraving, advertisement board, exhibition plate, logo plate

4)Transportation industry:

Ship, plane, bus, and train, floor covering, core layer, indoors decoration plate

Industrial application:

Suitable for rot-proof project in chemical industry, thermal forming, refrigeration warehouse

Features of PVC Foam Board Extrusion Line:

|

Material:

|

Virgin PVC/Recycled PVC

|

|

Product width:

|

1220mm

|

Product thickness:

|

3 - 25mm

|

Output range:

|

400 - 800kg/h

|

Main Parts details of ASA Casting Film Extrusion Line:

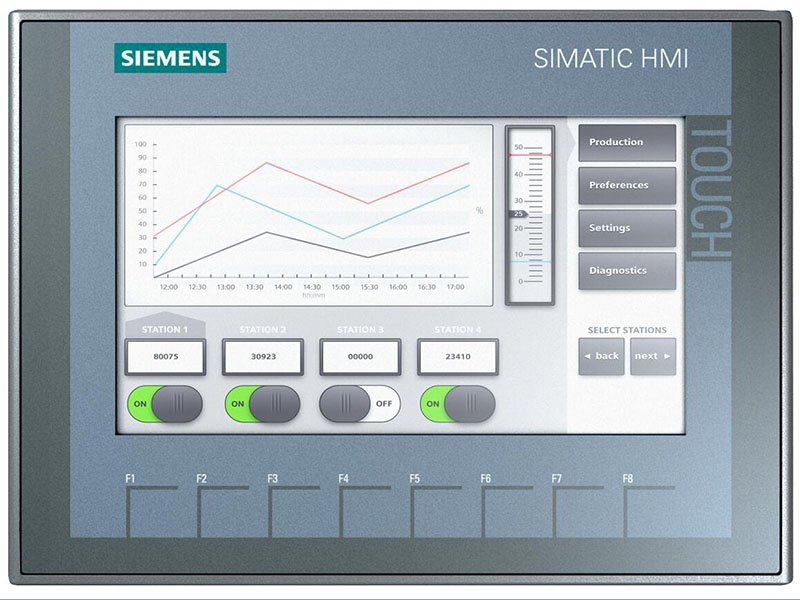

Siemens PLC + HMI Control System

✔ Siemens PLC + HMI control to assure the machine running precision and easy operation

Extruder

✔ Material of Screw: Bimetallic

✔ Specified screw design for better material plasticizing &mixing effect

✔ Reducer: High quality

✔ Siemens Main motor

✔ Capacity: 400-800kg/h

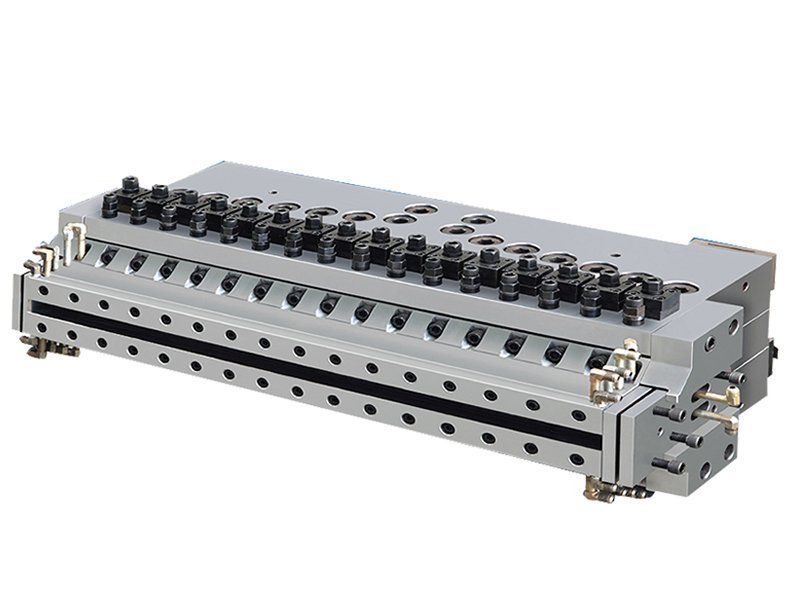

Die head

✔ Processing: High precision CNC to assure the high precision extruding

✔ Latest design: Adopt the Latest technology, which makes the operation more easy and less material wasting.

Clibration Table

✔ Processing: High precision CNC

✔ Qty of Calibration mould: 4Pairs

✔ Cooling method: water cooling

✔ Forming method: Vacuum suction

✔ Clamping method: Hydraulic or Pneumatic

Haul off Machine

✔ Qty of rollers: 8 or 10 Pairs

✔ Material of Roller: Rubber

✔ Haul off speed: 0-2m/min

✔ Clamping method: Pneumatic

Control Panel

✔ Siemens, ABB, Omron, Schneider, Dynisco etc